The PVC corner profiles are widely used in dry construction. Practically, when working with plasterboard, the corner profiles are mounted on every corner or edge. This ensures not only absolutely straight edges, but also strengthens the construction assembly.

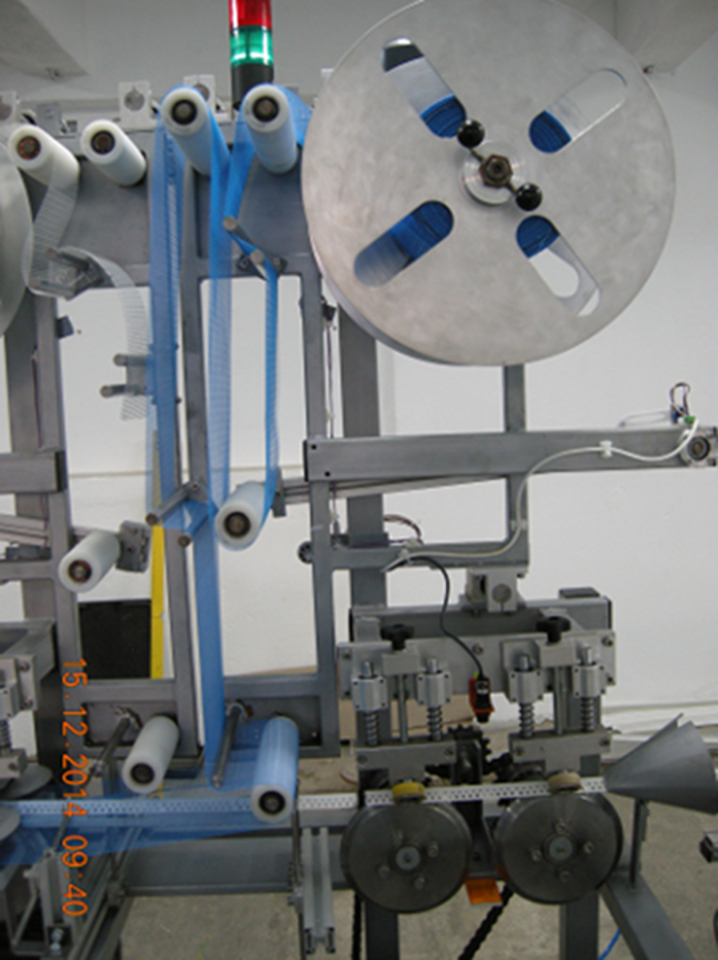

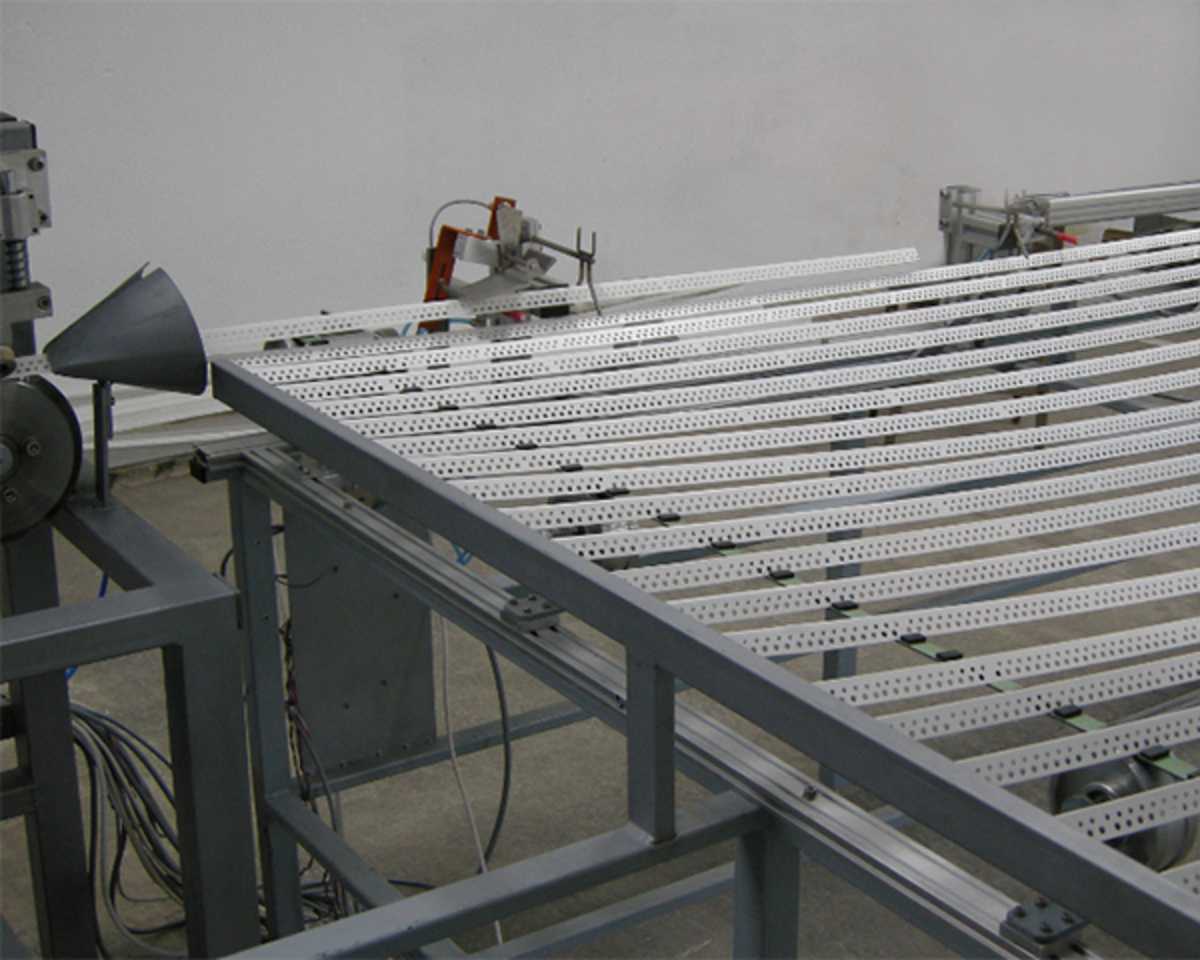

The machine for production of PVC corner profiles welds fiberglass mesh to profiles by using ultrasonic energy. The technology allows to avoid the use of adhesives and to increase productivity.

The machine is designed for production of two types of profiles. Readjustment is made by changing the parameters of feeding the fiberglass mesh. Machine’s productivity is 15 meters per minute, which makes it suitable for processing materials with identical characteristics.

Technical Parameters

Power supply: 400V, 50 Hz

Air supply: 4 - 8 bar

Ultrasonic power: 2 x 3000W / 20 kHz

Length of the mesh: 300 - 500 m for spool

Width of the mesh: max 250 mm

Material of the welding cord: PVC

Overall dimensions LxWxH: 14000 х 3000 х 2200 mm

Weight: 1500 kg

Video

Price

Price